Contents

Summary

A leading cracker manufacturer contacted Kudos Blends seeking a solution to reduce the sodium level in their crackers. A simple 1:1 exchange of sodium bicarbonate for KODA™ potassium bicarbonate significantly reduced sodium content and produced an indistinguishable end-product.

What KODA™ 50 Can Do for You

- Reduce sodium in crackers by up to 25% without compromising end-product volume and shape.

- Provide the same signature cracker taste, texture and appearance that customers expect.

- Ensure full dissolution of bicarbonate in low-moisture end products and prevent ‘bicarbonate spotting’.

- Be stored as a raw material for up to 3 years with no risk of compaction or loss in functionality.

- Replace sodium with the essential mineral potassium to improve the nutritional profile.

Our patented sodium reducing PELL™ K and KODA™ technology is also available for applications such as cakes, cookies, crumpets, tortillas, muffins, pancakes, doughnuts, premixes and many more. To find out more about how to improve the nutritional profile of your baked goods, contact our experts.

Background

A Fortune 500 food manufacturing giant reached out to Kudos Blends seeking a solution to reduce sodium in crackers whilst maintaining brand quality and end-product attributes, as they were aiming to improve their nutritional balance to meet health targets. Their sodium target was 700mg per 100g of end-product. Primary attempts at sodium reduction did not provide the required results:

- Replacing sodium bicarbonate with standard bakery-grade potassium bicarbonate negatively impacted flavour and created unsightly ‘bicarbonate spotting’.

- Replacing sodium bicarbonate with standard bakery-grade potassium bicarbonate fails to provide the same sensorial attributes and all-important texture.

- Reducing sodium chloride (salt) negatively impacted flavour.

Challenge

In crackers, sodium bicarbonate typically accounts for around 25% of the sodium present. As such, the most simple and effective way to reduce sodium is to replace sodium bicarbonate with a grade of potassium bicarbonate specialised for bakery applications.

Dry end-products are typically prone to suffer from ‘bicarbonate spotting’, whereby standard bakery-grade potassium bicarbonate does not fully dissolve within the cracker dough. This unreacted potassium bicarbonate gives an unpleasant taste and a very poor end-product appearance. It imparts a bitter, soapy flavour with a pale and spotted aesthetic. Additionally, it dampens functionality, meaning that there is a loss in overall volume and shape, leaving products with an underbaked and soggy texture.

Optimisation of particle size and prevention of baking powder clumping during storage is essential to keep the powder free-flowing, allowing it to fully dissolve in low-moisture batters and doughs.

Solution

Our patented KODA™ technology provides an unrivalled end-product result which can not only replicate the functionality of sodium bicarbonate but can also greatly reduce sodium and improve the overall nutritional profile.

Crackers made using different bicarbonate sources

Sodium

bicarbonate

866/100mg of sodium

KODA™ 50

potassium bicarbonate

654/100mg of sodium

Industry

potassium bicarbonate

654/100mg of sodium

Using KODA™ ensures full dissolution of bicarbonate in low-moisture end-products and prevents ‘bicarbonate spotting’ by providing application-specific particle sizing; all with a significant reduction in sodium levels.

Triangle Taste Test Comparison

To establish that our products don’t just look the part, a series of taste tests were conducted according to the following methodology:

Method based on ISO International Standard 4120:2021

Double-blinded, controlled conditions, bias minimised.

Three samples were given to testers. Two of them were identical controls, with the third containing KODA™ 50 instead of sodium bicarbonate. Testers are not privy to this information, which allows us to determine if any differences are truly distinguishable.

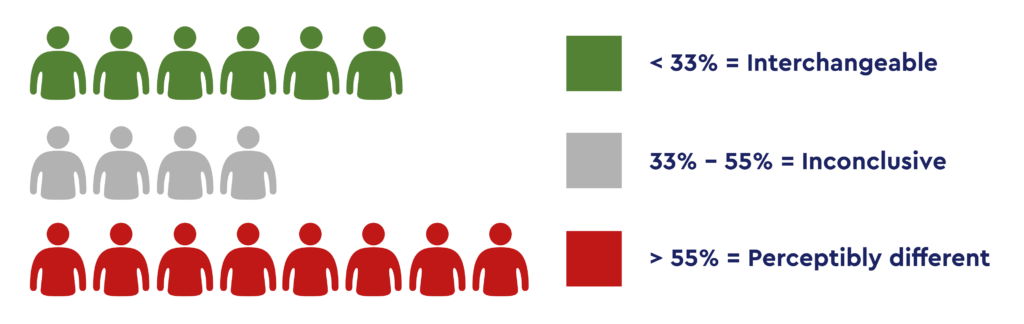

To be statistically significant, fewer than 33% of participants needed to correctly identify the difference for the product to be deemed ‘interchangeable’. Correct responses from between 33% and 55% make the test result inconclusive. Correct identification of differences by over 55% of participants means that the end product is ‘perceptibly different’.

| Samples | Percentage of correct identifications | Outcome |

| Sodium bicarbonate vs KODA™ 50 potassium bicarbonate | 27% | Interchangeable |

| Sodium bicarbonate vs Industry potassium bicarbonate | 83% | Perceptibly different |

Our KODA™ range offers a massive sodium reduction without compromising on taste, texture, volume and appearance.

As with all of our KODA™ range, KODA™ 50 has a 3-year shelf-life, meaning it can be stored for a prolonged period without any loss in functionality. It is available as both a complete baking powder as part of our PELL™ K low sodium range, or as an individual ingredient.