Summary

A leading premix manufacturer contacted Kudos Blends seeking a solution to reduce their sodium level in bakery premixes and concentrates. A simple 1:1 exchange of sodium bicarbonate for KODA™ potassium bicarbonate significantly reduced premix sodium content and extended the overall shelf-life by 50%.

What KODA™ 200 Can Do for You

- Reduce sodium in premixes by up to 40% without compromising end-product volume.

- Provide a quality end-product with an open, aerated crumb and a soft mouthfeel.

- Increase stability and shelf-life of premixes by up to 50%.

- Replace sodium with the essential mineral potassium to improve the nutritional profile.

Our patented sodium-reducing KODA™ technology is also available for applications such as cakes, crumpets, tortillas, muffins, doughnuts, pancakes, cookies, crackers, premixes and many more. To find out more about how to improve the nutritional profile of your baked goods, contact our experts.

Background

A global premix manufacturer aimed to reduce sodium in a crème cake premix without losing quality or shelf-life, as they were facing pressure to meet sodium reduction targets introduced in the UK. Initial sodium reduction methods did not provide the results they required:

- Replacing sodium bicarbonate with standard bakery-grade potassium bicarbonate significantly reduced the shelf-life of the premix compared to sodium bicarbonate.

- Reducing sodium chloride (salt) had little impact on overall sodium content and negatively impacted flavour.

- Replacing sodium acid pyrophosphate (SAPP) with a calcium-based acidulant resulted in cakes with a poor volume and an undesirable crumb structure.

Challenge

Sodium bicarbonate accounts for up to 50% of the sodium present in chemically leavened baked goods. As such, the most simple and effective way to reduce sodium is to replace sodium bicarbonate with a grade of potassium bicarbonate specialised for bakery applications. Premix and concentrate manufacturers often require product-specific features from the potassium bicarbonate used in their recipe to ensure the highest quality baked goods every time.

Dry blends contain many ingredients which must all remain stable and inactive throughout storage, whilst ensuring their total functionality when the product is eventually baked in order to guarantee texture, volume and flavour.

An increased particle size will decrease the available surface area for premix particles to interact and react during storage. Therefore, the particle size of the potassium bicarbonate must be perfectly balanced to ensure full solubility and functionality when creating batters, but not so fine as to reduce the stability during the shelf-life of the premix or concentrate.

Solution

The particle size of KODA™ 200 potassium bicarbonate has been specifically engineered to achieve equal or greater shelf-life in a premix when compared to sodium bicarbonate, all whilst offering a significant sodium reduction, without impacting the volume, texture or taste.

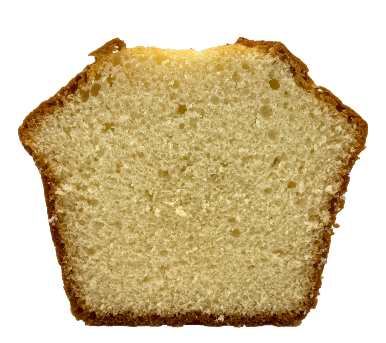

The images below demonstrate the significant improvement in overall quality observed when using KODA™ 200 compared to a competitor’s bakery-grade potassium bicarbonate. Testing was conducted using a Madeira cake premix manufactured 12 months prior to baking. All cakes were made with identical premix recipes, with only the bicarbonate source changed.

Premixes Made Using Different Bicarbonate Sources

Sodium

bicarbonate

424mg/100g of sodium

KODA™ 200

potassium bicarbonate

272mg/100g of sodium

Industry potassium bicarbonate

272mg/100g of sodium

Standard bakery-grade potassium bicarbonate produced a product with a dense crumb, poor volume, and a poor texture; in part linked to its poor functionality preventing sufficient moisture from being driven off. KODA™ 200, on the other hand, offers like-for-like finished goods; with a 36% decrease in sodium levels.

The KODA™ 200 premix not only matched the shelf life of sodium bicarbonate, but further testing showed that KODA™ 200 reached 18 months of stability with no loss in volume or overall quality; 6 months longer than sodium bicarbonate.

Thanks to our patented free-flow technology, as with all of our KODA™ range, KODA™ 200 has a 3-year shelf-life, meaning it can be included in chemically-leavened premixes and stored for a prolonged period without any loss in functionality.