Contents

Summary

Replacing the functionality and leavening capacity of sodium bicarbonate can be challenging. Renowned for its long-term stability and ability to fully dissolve in batters, it is undeservedly favoured over significantly healthier alternatives. A simple transition to one of our PELL™ K low sodium baking powders, utilising our patented KODA™ technology, offers the same functionality, solubility and end-product quality, all with a massive reduction in sodium.

What PELL™ K-Rise Can Do for You

- Reduce sodium in the recipe by up to 50%.

- Retain the same volume and crumb structure of the cake without sodium bicarbonate.

- Leave the physiochemical properties unchanged, to provide the same high-quality taste and texture that customers expect.

Our patented sodium reducing PELL™ K and KODA™ technology is also available for applications such as cookies, crackers, crumpets, tortillas, muffins, pancakes, doughnuts, premixes and many more. To find out more about how to improve the nutritional profile of your baked goods, contact our experts.

Background

In the UK, salt reduction targets are in place for 2024, calling the bakery industry into action to meet new legislation and customer health needs. Public Health England now recommends another 6% salt reduction in cakes, with further decreases on the horizon.

Salt, known as sodium chloride, comprises of 60% chloride and 40% sodium. Sodium itself is an essential mineral that plays a crucial role in our health. However, consuming excessive levels can result in dangerous negative health effects.

While bakery items may not be immediately associated with high salt levels, a typical chocolate cake can contribute to our daily sodium intake by as much as 360mg per 100g. This is equivalent to 15% of the recommended daily allowance (RDA) per slice.

Challenge

Sodium bicarbonate, commonly known as bicarbonate of soda, has been conventionally used as a leavening agent for over a century. More recently, the dangers to health that sodium possesses have become increasingly apparent. However, emulating the functionality of sodium bicarbonate without compromising on the end-product quality has proven difficult.

The ‘bicarbonate’ component of sodium bicarbonate is critically responsible for the release of carbon dioxide, which produces a leavening action in baked goods. In order to retain end-product volume, taste and texture, whilst simultaneously reducing sodium, an alternative bicarbonate source is required.

Solution

Here at Kudos Blends, we offer a patented sodium-free alternative to sodium bicarbonate. KODA™ potassium bicarbonate enables manufacturers to create bakes that meet legislation and consumer preferences.

KODA™ is a single ingredient and just one agent of a complete baking powder. That is why we have a range of complete, low sodium baking powders that encompass all the perks that KODA™ has to bring with the perfect ratios of leavening, in one ready-to-go blend.

PELL™ K-Rise has been chemically formulated to create the perfect rise with reduced sodium levels, helping adhere to government regulations, as well as improving consumer health; all with no impact on quality and taste.

Employing a cake manufacturer’s recipe, we replicated the formula in our controlled test kitchen, ensuring consistent variables for both cakes.

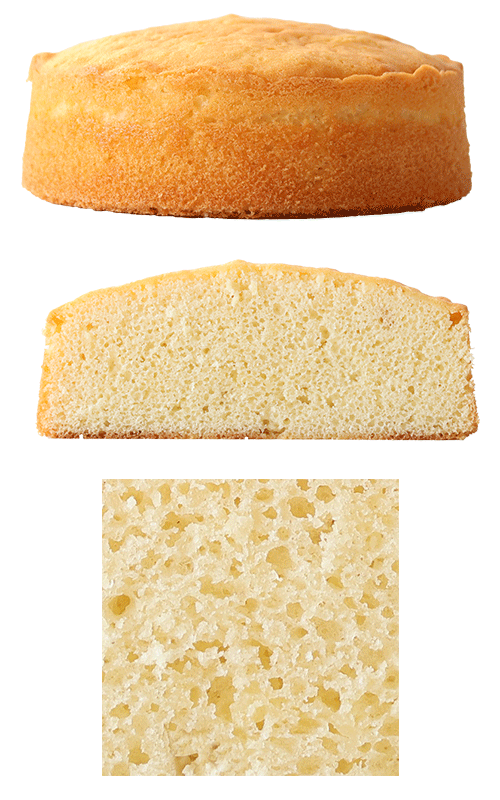

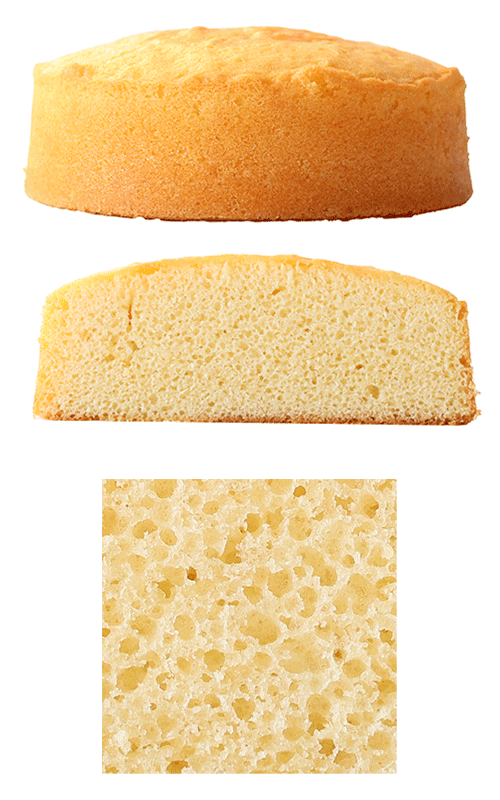

PELL™ Restrain

PELL™ K-Rise

Measurements

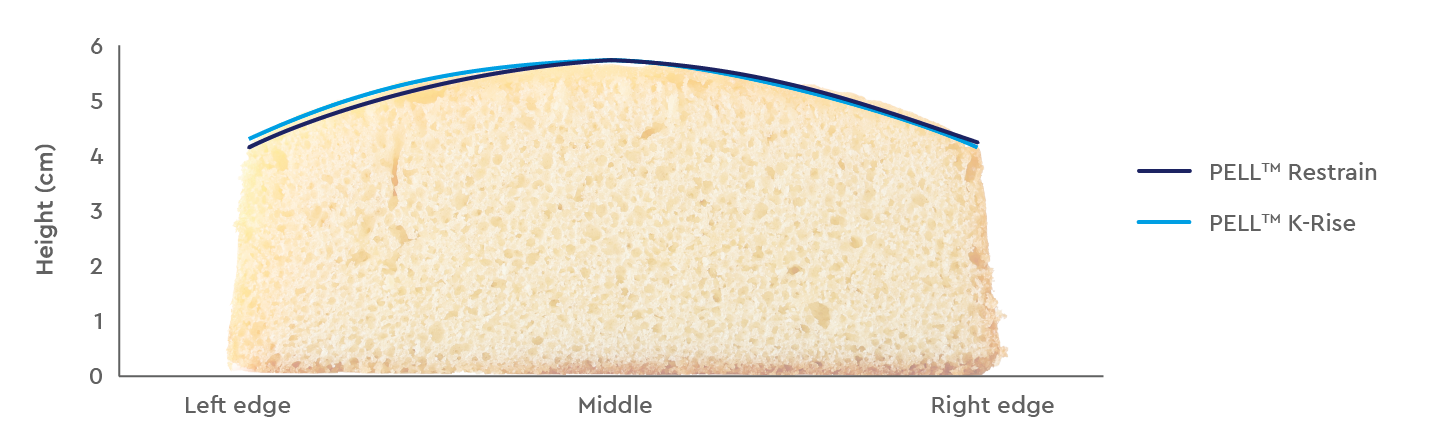

Fig. 1. Average measurements of the final product. The higher the line, the greater the volume.

Both the external and internal appearance of the end products displayed no significant differences, with both sponges displaying a soft open aerated crumb, tall shoulders and a bright internal colour. As well as the overall appearance, the cake measurements displayed almost identical total volume indexes.

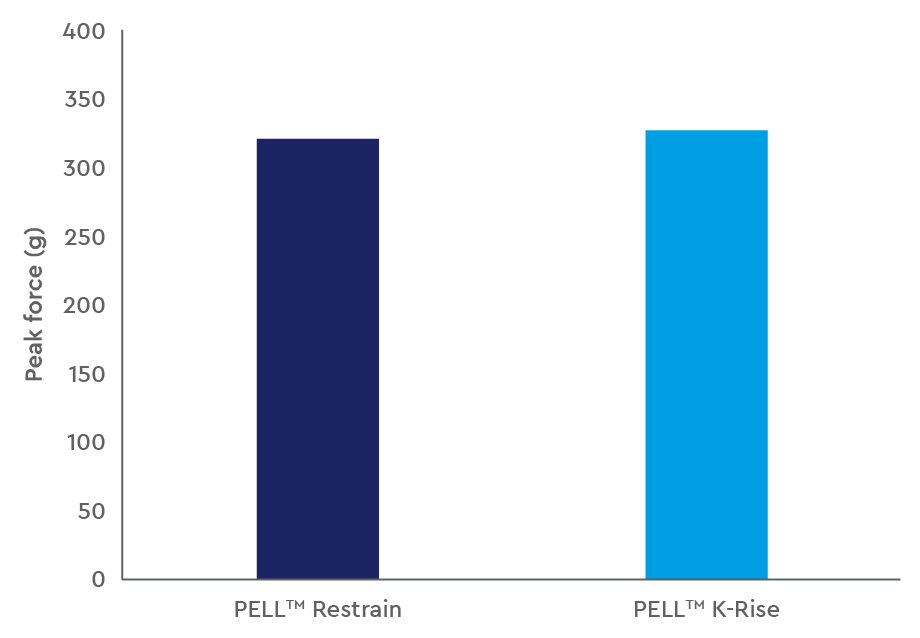

Hardness

Fig. 2. The higher the peak force, the harder the product

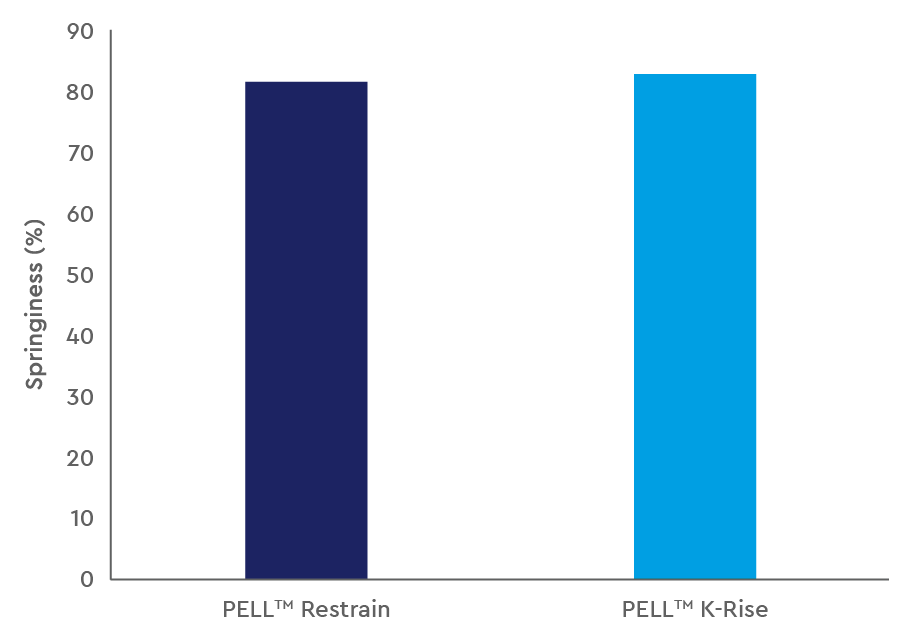

Springiness

Fig. 3. The higher the bar, the springier the product.

Using statistical analysis of variance (ANOVA), no significant differences were found between both cakes. Both cakes had statistically similar hardness and springiness and when organoleptic tests were conducted, it was concluded that the two cakes displayed the same mouthfeel properties.

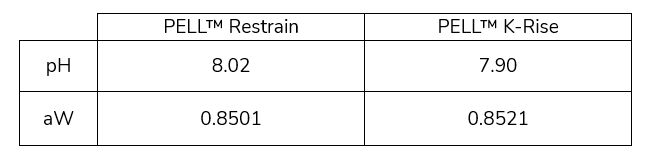

Physiochemical Properties

Fig. 4. A chart displaying the water activity (aW) and pH in both end-products.

Both the pH and water activity in the end products again displayed no significant differences, leaving manufacturers reassured that there are no impacts on the overall quality and shelf-life of the product.

On top of the health benefits, the end products display the same visual appearance, textural attributes and mouthfeel when using PELL™ K-Rise when compared with a standard baking powder. The use of PELL™ K-Rise also adds potassium, which is a useful tool for improving wellbeing; such as improving heart health, blood pressure regulation, and muscle function.

The only differences are found within the nutritional balance of the cake. Through simply replacing the baking powder in the final recipe, PELL™ K-Rise, which uses our patented KODA™ technology, makes it possible to achieve a reduction of 47% in sodium when compared to a standard sodium bicarbonate-containing baking powder.