Contents

Summary

Consistently achieving tall, uniformly peaked, big fluffy muffins can be challenging. The use of single-acting baking powders often results in inadequate gas retention, preventing the desired late-stage burst necessary for a perfectly peaked muffin. Improving both the muffin volume and peak can be as easy as changing to one of our PELL™ double-acting baking powders.

What PELL™ Vesuvius Can Do for You

- Increase end-product volume, creating a bigger muffin whilst using the same deposit weight.

- Create a more desirable internal crumb structure and improve the overall mouthfeel of the muffin.

- Produce improved peaked muffin tops thanks to the delayed burst of gas when baking.

Our volume boosting PELL™ technology is also available for applications such as madeira cakes, doughnuts, pancakes, and many more. To find out more about our double-acting baking powders, contact our experts.

Background

The global muffin market was valued at $8 billion US dollars in 2022. That figure is set to rise in the coming years thanks to new hybrid flavours, seasonal specials and even savoury muffins being introduced. In addition to flavours, other driving forces such as technological advancements and evolving consumer demands also influence the muffin market.

Bakery-style muffins are often found in cafes and supermarket in-store bakeries; the volume and shape of which play a pivotal role influencing both the visual appeal and the overall eating experience for consumers. A well-defined shape and ample volume contribute to a desirable texture, achieving a balance between fluffiness and density for a moist and tender crumb.

Challenge

Often, when using single-acting baking powders, most of the gas is lost before the muffin batter even enters the oven. This is down to the fact that these baking powders only require the addition of water to begin releasing carbon dioxide (CO₂). As such, a muffin batter created using single-acting baking powders can result in unleavened, flat and dense end-products. In order to achieve muffins with good volume, cracked tops, and a fluffy texture, the gas release needs to occur at multiple points throughout the baking process.

Solution

Our team of chemists and bakers have developed PELL™ Vesuvius to achieve the ideal balance for a two-stage gas release, ensuring the creation of the perfect muffin within the parameters of industrial manufacturing processes.

It is a double acting baking powder delivering gas in a two-stage process:

- Aerating the batter during mixing, nucleating the mix with CO₂.

- Maximising volume when baking with a late burst of gas during baking.

Why Double?

Double-acting baking powder is a leavening agent commonly used in baking, including muffin recipes. It works in two stages, hence the term “double-acting”. The two stages refer to the chemical reactions that occur at different points in the baking process.

First Action (Acid-Base Reaction)

The baking powder contains both an acid and a base. When double-acting baking powder is mixed with the wet ingredients in the batter, it initiates an acid-base reaction. The acid reacts with a base to produce carbon dioxide gas. This reaction begins as soon as the batter is mixed, creating bubbles in the batter.

Second Action (Heat-Activated Release of Carbon Dioxide)

The second phase of the double-acting process occurs when the batter is exposed to heat during baking. The heat causes the release of additional carbon dioxide gas, contributing to the leavening or rising of the muffins. This delayed action is beneficial because it allows the batter to rest for a short time before baking and it continues to produce gas during the initial stages of baking.

The combination of these two actions helps create a light and fluffy texture in muffins.

The application of PELL™ Vesuvius yielded a notable increase in volume, even when the muffins were made using identical deposit weights. This surge in volume significantly enhances the overall quality of the muffin, leading to a more appealing internal crumb structure and an enhanced mouthfeel.

PELL™ Vesuvius on the right displaying an increase in volume and a more peaked muffin top.

The muffin that used a standard single-acting baking powder displayed a dense line on the top. This is a result of not having that second burst of gas to enable the creation of a peaked top.

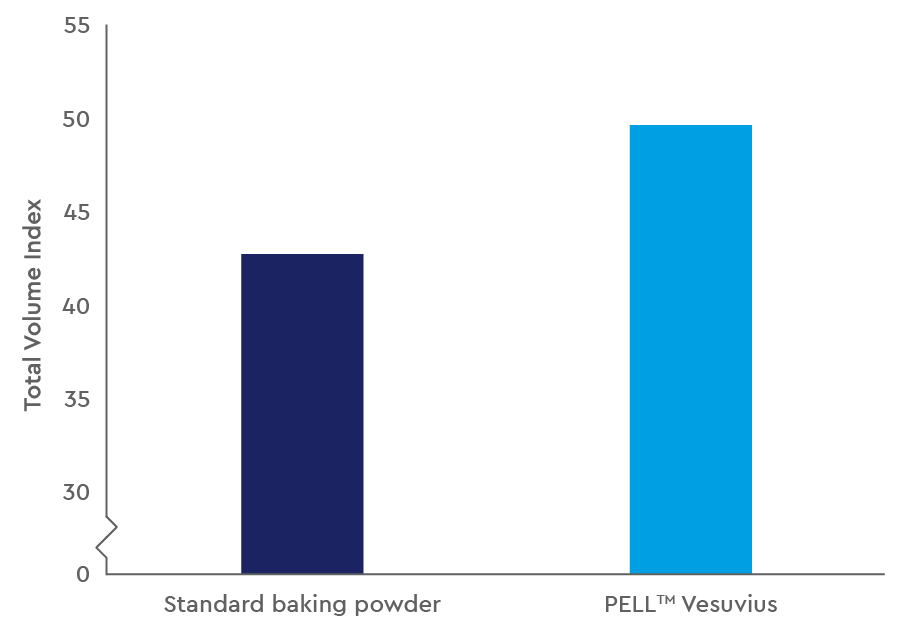

Improvements in Volume

Fig. 1. Average measurements of the final product. The higher the bar, the larger the product.

With increased muffin volume, manufacturers will see a significant improvement in the end-product results without the need for recipe reformulation. Thanks to rigorous on-site raw material and batch tests in our laboratory, you can rest assured that the product will perform well every time. And with an 18-month shelf-life, PELL™ Vesuvius is able to help you create perfectly peaked muffins beyond the calendar year.