Contents

Summary

The use of sodium aluminium phosphate (SALP) as a leavening acid is becoming increasingly limited worldwide due to global legislative changes triggered by aluminium’s link to negative health effects. It’s becoming more important than ever to find effective aluminium-free alternatives for the baking industry. The OPUS™ SALP Replacer range is an excellent and easy swap for conventional SALP acidulants whilst maintaining or improving all original characteristics in a huge variety of products; without aluminium.

What OPUS™ SALP Replacers Can Do for You

- Mimic the reaction profile of SALP and maximise end-product volume.

- Provide the same quality, shape and taste without the aluminium and negative health impacts.

- Ensure a fine, resilient and bright crumb.

Our aluminium-free OPUS™ acidulant technology is also available for applications such as sponge cakes, scones, doughnuts, tortillas, premixes and many more. To find out more about our SALP replacing products, contact our experts.

Background

Following research developments linking aluminium consumption to neurodegenerative diseases such as Alzheimer’s, SALP has been banned by EU legislation since 2014, with many countries worldwide following in this action. Designed in 2013, in anticipation of SALP bans, our OPUS™ SALP replacer uses a unique blend of alternate leavening acids carefully chosen to replicate the specific functionality of SALP.

This is a crucial product and is growing in demand, as despite SALP being banned in Europe since 2013, the rest of the world are only recently beginning to take action, this includes emerging markets in Brazil, Thailand, Australia and New Zealand.

Challenge

SALP has been a commonly used food ingredient globally for many years, most significantly as a leavening acid in baking powders. In a baking powder it reacts with sodium bicarbonate in a simple 1:1 ratio.

Historically, it has been successful as a leavening acid for two reasons. Firstly, due to its ability to impart such a fine crumb structure and texture in baked goods. Secondly, it reacts very slowly in room temperature batters; only when subject to heat will it fully react to release carbon dioxide. As such, replacing this highly functional and widely adopted ingredient is a difficult challenge.

Solution

OPUS™ SALP replacer has been developed using a specific blend of leavening acids, in unity with new leavening technologies to provide aluminium-free replacements for SALP.

Our OPUS™ range is easy to use and has been carefully designed to replicate SALP’s ability to impart a fine, resilient and bright crumb in baked goods. It is a highly functional acidulant blend that can be used with either sodium or potassium bicarbonates, such as KODA™, to react and release carbon dioxide. Our product does not adversely affect any aspect of the process and therefore does not require any changes to recipe formulation.

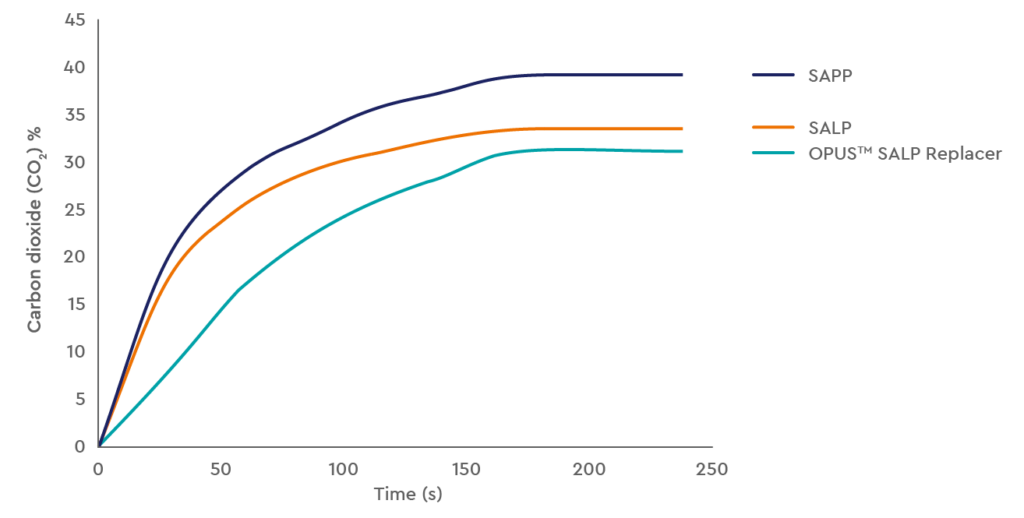

Rate of Reaction

Sodium acid pyrophosphate, commonly known as SAPP, is another leavening acid that is often used to replace SALP in the baking industry. Compared to SALP and OPUS™ SALP replacer, SAPP has a much faster rate of reaction when combined with bicarbonates, and therefore will not replicate the reaction profile of SALP.

Dough Rate of Reaction (DROR) of

SALP, SAPP and OPUS™ SALP Replacer

Fig. 1. DROR of SALP and SAPP compared to OPUS SALP Replacer showing the gas release over time in a simulated dough system.

OPUS™ has a significantly more similar reaction profile to SALP compared with SAPP. If too much gas is released too quickly, the cake is at risk of collapsing. The slower rate of reaction of SALP and OPUS™ products allows for more carbon dioxide production and rise in the oven before the cake structure sets and the starch gelatinises, so that a better end-product shape and volume can be achieved.

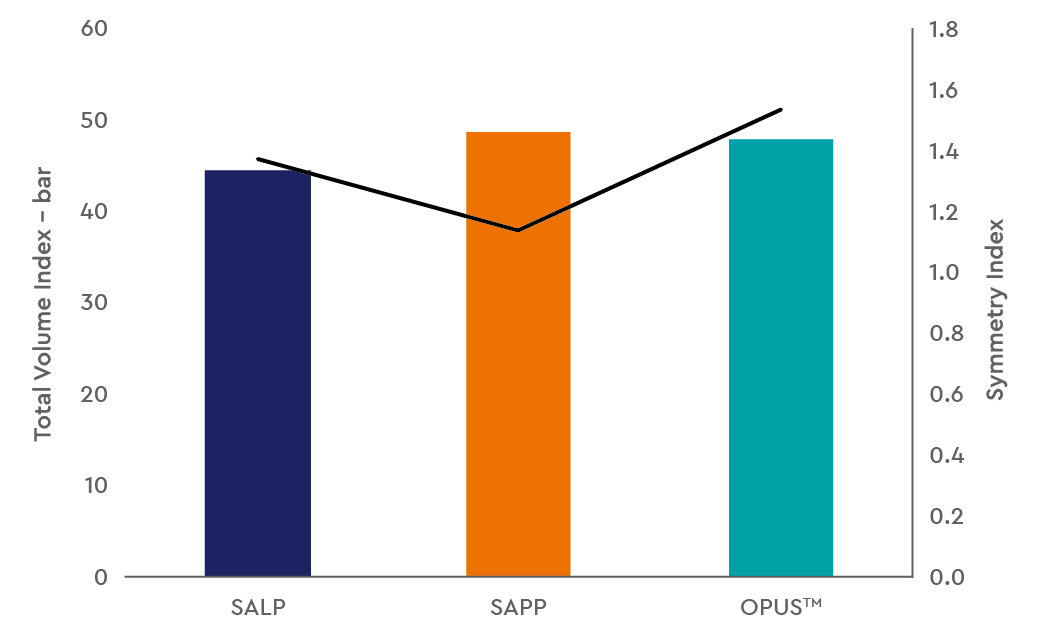

In this example of a basic Madeira loaf cake, we are looking to assess if SALP can simply be replaced by OPUS™ SALP replacer without losing the specific characteristics that SALP brings.

SALP

Sodium aluminium phosphate

SAPP

Sodium acid pyrophosphate

OPUS™

SALP replacer

Measurements

Fig. 2. Average measurements of the final product.

The higher the bar, the larger the volume.

The higher the line, the more of a central peak the cake has.

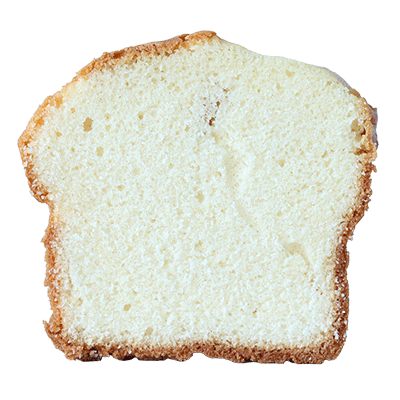

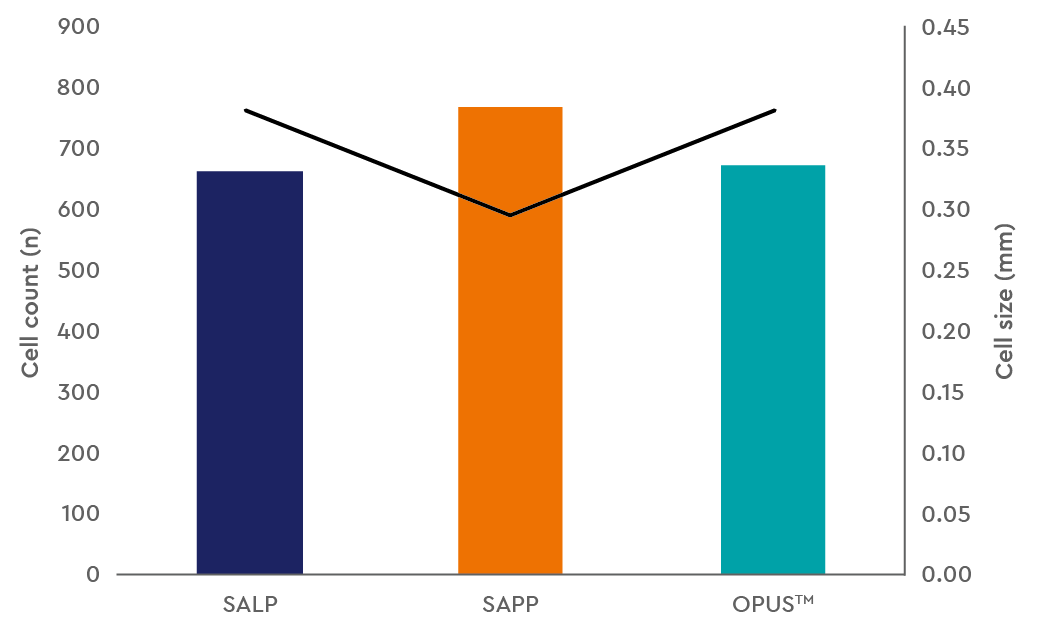

Crumb Cell

Fig. 3. The average crumb structure of the final cake.

The higher the line, the more individual cells there are, indicating a finer crumb.

The higher the bar, the larger those individual cells are.

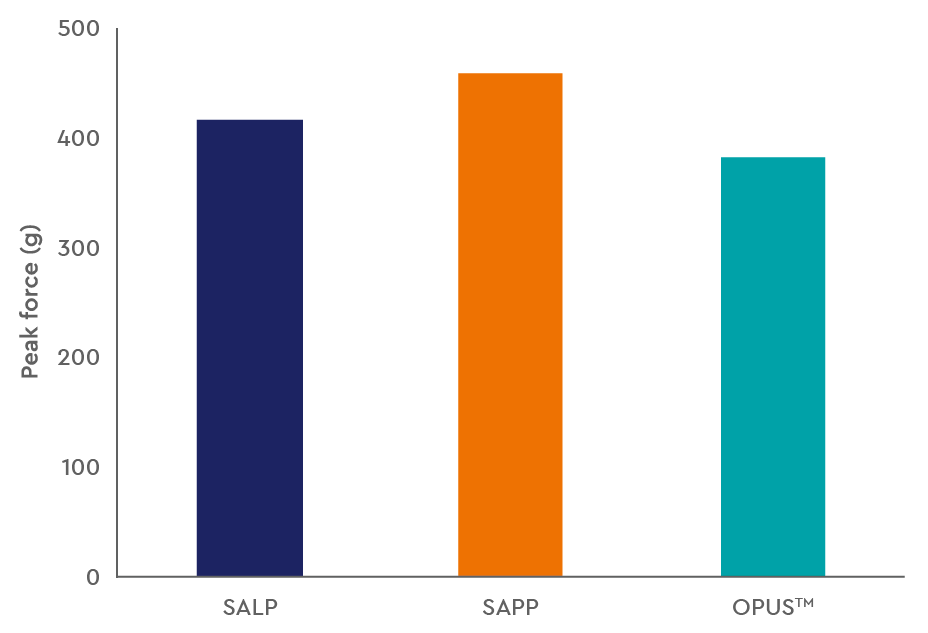

Hardness

Fig. 4. The higher the peak force, the harder the product.

These results clearly display that OPUS™ SALP replacer creates much more similar results in a cake than replacing SALP with SAPP, leaving the manufacturer with a SALP replacement that is both aluminium-free and successfully replicates the preferred SALP characteristics. All of this whilst also leaving the consumer with healthier baked goods.

OPUS™ SALP replacer mimics the characteristics of SALP in your baked goods throughout its 2-year shelf-life, and can be used with both sodium bicarbonate as well as our patented KODA™ potassium bicarbonate.