Contents

Summary

For bakeries with large production lines or complex processes, maintaining a consistent and accurate time between mixing and baking can be difficult. With changes in processing times, it can lead to variations in texture, taste and overall appearance, affecting uniformity. A simple change to PELL™ Restrain baking powder allows manufacturers to make a consistent product, even if the cake batter sits in the mixer for a few hours, which can save money, time and prevent ingredients from going to waste.

What PELL™ Restrain Can Do for You

- Provide exceptional batter hold tolerance for over 4 hours.

- Improve end-product aeration and a create more robust crumb.

- Increase overall end-product output, reducing both wastage and cost.

Our tolerance enhancing PELL™ technology is also available for applications such as doughnuts, pancakes, crumpets and many more. To find out more about our double-acting baking powders, contact our experts.

Background

Navigating the complexity of process tolerance became especially daunting for one of the United Kingdom’s leading suppliers of premium hand-finished cakes and traybakes to the retail market. In the wake of staffing shortages exacerbated by the effects of the coronavirus (COVID-19) pandemic, the cake manufacturer faced a critical need for a solution that could increase the resilience of their baked goods in to navigate variations in hold time. This prompted them to contact the team at Kudos Blends.

The collaboration aimed to identify a specialised baking powder capable of mitigating the challenges posed by the unpredictable fluctuations in processing times, ensuring that the bakery’s commitment to delivering consistently high-quality products remained unwavering, even amid the rocky circumstances presented by the pandemic.

The ultimate goal was not only to address the immediate staffing challenges but also to fortify the bakery’s processes for long-term resilience and adaptability in an ever-evolving market.

Challenge

Any delay or acceleration in industrial baking processes can disrupt the delicate balance required in baking. If too much time passes whilst the batter is held, a significant portion of carbon dioxide (CO₂) is lost from the batter, resulting in undesirable outcomes such as uneven rising or loss of volume, creating huge losses for manufacturers who are left with unsellable end-products.

It’s not just about money; there are also considerable environmental impacts. Delays in industrial-scale production can result in hundreds of kilos of cake batter becoming unusable. If a solution cannot be found right away, you have to either throw away the batter because too much time has passed, or once it is fixed, risk baking cakes that might not meet quality standards.

Solution

PELL™ Restrain is a baking powder that offers exceptional process tolerance due to its unique blend of leavening acids. It promotes a small amount of carbon dioxide nucleation during the mixing stage (the formation of tiny air bubbles into which further CO₂ diffuses during baking) which improves oven spring, leading to greater cake volume. The rest of the gas is not released until the product goes into the oven, ensuring the cake batter remains stable during its holding time and improving overall consistency.

Using our on-site test bakery and state-of-the-art analysis suite, the team at Kudos Blends were able to replicate the recipe and conditions of the manufacturing site and their process, in order to demonstrate the benefit of PELL™ Restrain over standard baking powders.

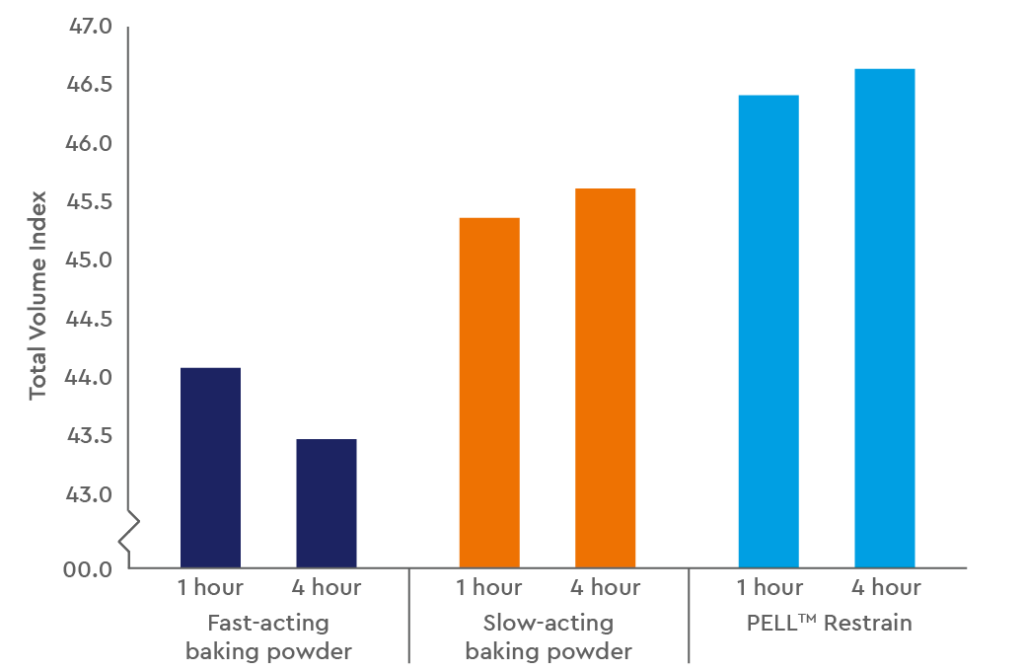

Cake Volumes After Different Hold Times

Fig. 1. Volume measurements for cakes held for different lengths of time at room temperature before baking.

Volume indices measured according to AACC Approved Method 10-91.

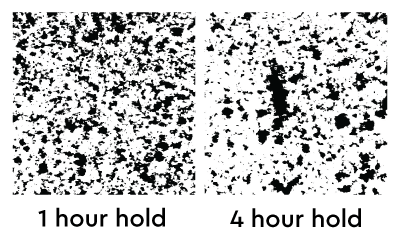

The bakery results demonstrated that, as hold time is increased, fast-acting baking powders produced gas early on which escaped from the batter during its holding phase, resulting in a rapid loss of volume over time (Figure 1). Image analysis, which assesses the size and number of air cells within the finished cakes, showed that any remaining gas bubbles in these cakes readily coalesced (Figure 2), leading to large holes and a weaker structure once baked.

Slow-acting baking powders, on the other hand, retained their volume and did not undergo the same degree of bubble coalescence. However, initial volumes were also lower.

Fast-acting baking powder

PELL™ Restrain

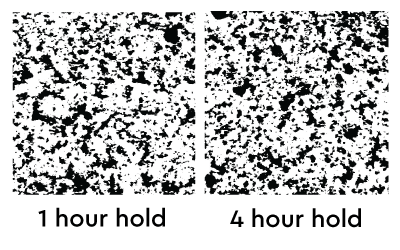

Fig. 2. Crumb structure images of baked cakes. Black regions indicate air pockets.

PELL™ Restrain produced the best results, not only showing minimal volume loss and maintaining a fine crumb structure even after a 4-hour hold time, but also producing cakes with the greatest volume due to the promotion of carbon dioxide nucleation during mixing.

Get in touch with our experts to find out more.