Contents

Summary

Phosphates have been a large part of chemical leavening in the bakery industry since the 1800s, and are some of the most effective leavening acids. They offer controlled reaction speeds and excellent functionality.

While there have been multiple instances of phosphate shortages and supply issues over recent years, one of the most significant examples was the phosphate crisis of 2018. This this led to supply and demand issues globally, which caused the prices to skyrocket. Equally, consumers are becoming increasingly aware about the sustainability of their food choices, causing increasing pressure on bakery manufacturers.

As leavening agent specialists, the team at Kudos Blends used this opportunity to apply the science behind baking to create an innovative range of baking powders that easily achieve phosphate replacement. These baking powders provide the same functionality and stability that phosphate-containing acids have provided for many years.

What ZEUS™ G90 Can Do for You

- Provide phosphate-free leavening in a variety of baked goods.

- Improve sustainability claims and consumer appeal.

- Provide added pH reduction benefits.

Our phosphate-free baking powder can be used in a wide range of bakery applications, including cakes, scones, muffins, doughnuts, premixes and many more.

Background

Within the food industry, particularly the production of baked goods, phosphates have been fundamental. Commonly used phosphates include sodium acid pyrophosphate (SAPP), sodium aluminium phosphate (SALP) and monocalcium phosphate (MCP). These all react well with sodium or potassium bicarbonate within a baking powder system to produce carbon dioxide gas and perfectly aerate baked goods.

The problem is, phosphates are a finite resource, and the world’s reserves are depleting. There were significant shortages in 2018 and again in 2022, which caused severe supply and demand issues and cost fluctuations. It’s also important to note that volatility of supply is not the only problem here, but the majority of the world’s supply comes from countries like Morocco, China, Algeria, Russia and the US, so political and economic issues put more pressure on stability, supply and pricing.

The bakery industry only receives a small proportion of the world’s phosphates, with the majority going into the agricultural industry in the form of fertilisers. With the population ever growing, this use is only going to put more pressure on the supply chain. Aside from supply issues, consumers are becoming increasingly aware of what they are eating and care more than ever about their environmental impact, so some may be looking to avoid phosphates in products they purchase.

Challenge

The baking industry relies heavily on phosphate-based acidulants for their superior functionality and controlled gas release, which helps achieve the optimal volume and texture in baked goods.

Many alternatives, such as the majority of organic acids, are unsuitable for large-scale manufacturing due to their fast reaction speeds, which begin as soon as moisture is added. With a large portion of the acid-bicarbonate reaction taking place prematurely, in the bowl, this leaves little gas to be released during baking.

This results in reduced oven spring, low volume, and a dense, claggy texture in the finished product. The core challenge is to create a phosphate-free baking powder that mimics the profile of traditional phosphates.

Solution

Our solution is ZEUS™ G90 baking powder, a phosphate-free system that utilises novel leavening technology.

Standard Baking Powder – Containing Phosphates

ZEUS™ G90 Baking Powder – Phosphate Free

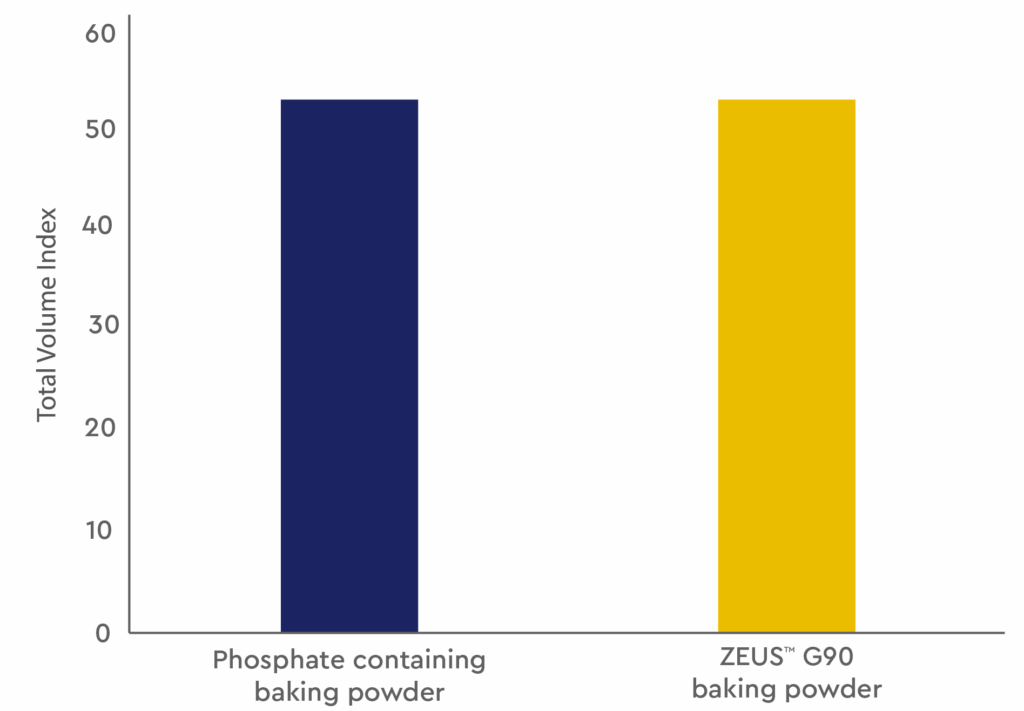

To put this to the test, our case study shows a cake with a standard baking powder, and one with our phosphate-free, ZEUS™ G90 baking powder for comparison. The cakes were very similar visually, and the volumes were also statistically comparable.

Total Volume Index

Added Benefits

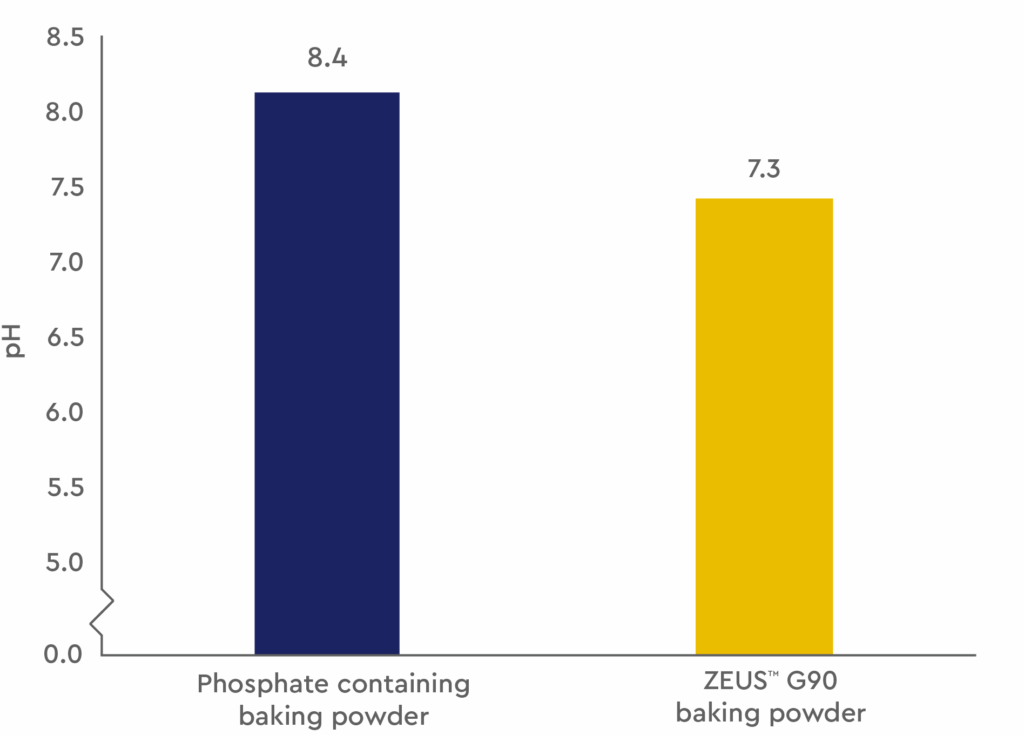

Looking into the chemical properties, this ZEUS™ technology allows for reduced pH in baked goods. This will bring added benefits to the product and assist with shelf life if preservatives are present. It will also increase the crumb brightness, and if natural colours are being used, the colour stability will be improved.

pH

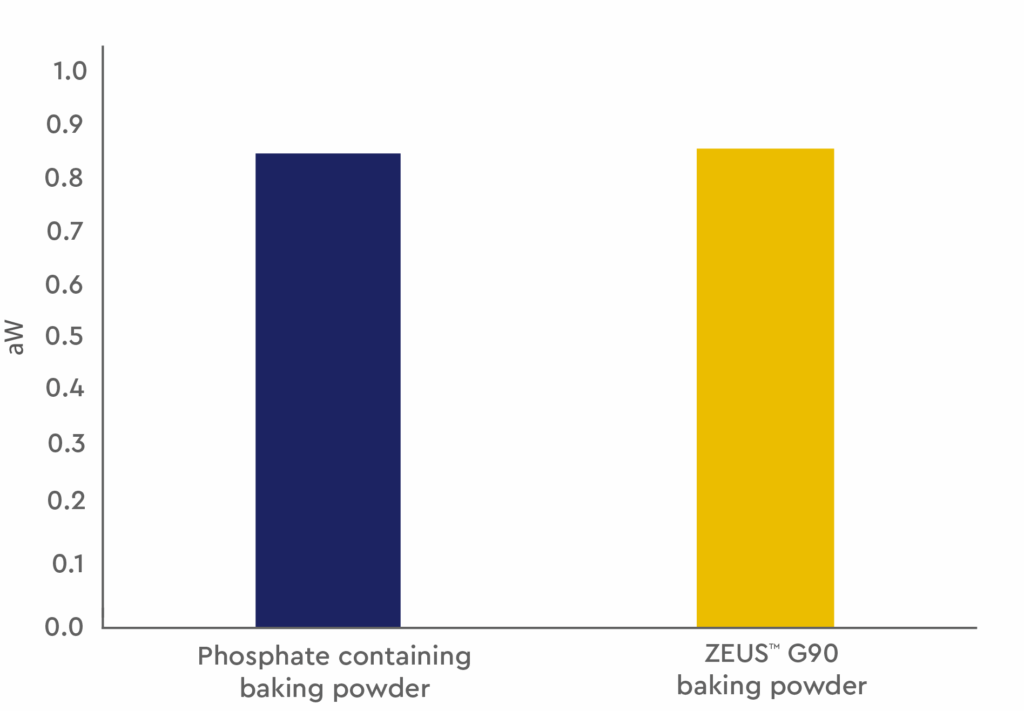

Water Activity (aW)

The water activity (aW) was very similar between the trial samples, meaning there will not be an increased likelihood for microbial growth.

Conclusion

In summary, while phosphates have historically been indispensable in chemical leavening technology, ZEUS™ G90 baking powder provides an excellent alternative. It replicates the functionality and performance of traditional, phosphate-based baking powders, shown by the highly comparable data from our trials and very similar bakes. Aside from its performance, ZEUS™ G90 mitigates supply chain issues, while also being more appealing to consumers who are driven by reducing their environmental impact. ZEUS™ G90 is helping us secure the future of chemical leavening in the bakery industry.

Reach out to our team to discuss how our phosphate-free baking powder, ZEUS™ G90, can help eliminate potential supply issues and improve sustainability within your business.

-

Do phosphate-free baking powders help with clean-label reformulation?

They do. Our ZEUS™ phosphate-free baking powders are well-suited to cleaner-label reformulations. Although chemical leavening as a rule is not clean, by removing traditional phosphates such as SALP, manufacturers can simplify ingredient lists and reduce the use of chemically derived leavening acids.

-

What bakery applications are your phosphate-free systems suitable for?

Our range of phosphate-free baking powders can be used in a wide variety of baked goods, from pancakes to muffins.

-

Are your ZEUS™ phosphate-free baking powders gluten-free?

Yes! All of our ZEUS™ baking powders are manufactured in our dedicated gluten-free facility.