Contents

Summary

Sodium aluminium phosphate (SALP) is an excellent leavening acid that has been used for many years due to its easy 1:1 usage ratio with sodium bicarbonate, as well as its ability to impart a fine, bright crumb to baked goods.

However, health related concerns related to aluminium intake in baked goods have been raised by consumers and governmental agencies in several countries. These concerns often revolve around potential health risks associated with aluminium accumulation in the body over time, particularly its links to neurological disorders, such as Alzheimer’s, as well as other health issues.

Our OPUS™ SALP replacer has been designed to, match the reaction profile and characteristics of SALP to provide the same great end-product, while eliminating the use of aluminium and its risks.

What OPUS™ SALP Replacers Can Do for You

- Provide the same quality, shape and taste while removing the aluminium and its associated negative health impacts.

- Mimic the reaction profile of SALP and maximise end-product volume.

- Ensure a fine, resilient and bright crumb in your baked goods.

Our aluminium-free OPUS™ range of acidulant blends can be used in a wide range of bakery applications including sponge cakes, scones, doughnuts, tortillas, premixes and many more.

Background

Research has revealed that the consumption of aluminium may be linked to neurodegenerative diseases such as Alzheimer’s. As a result, SALP has been banned by European Union legislation since 2014.

Globally, concerns over aluminium intake have gained momentum, leading to significant changes in key markets. In the United States, while SALP remains classified as Generally Recognized As Safe (GRAS) by the FDA, growing consumer awareness and recent legislative efforts, such as the Agricultural Food Chemical Reassessment Act of 2024, signal a shift toward reevaluating the safety of aluminium-containing additives in food.

As more countries inevitably follow the EU’s lead, combined with rising consumer demand for cleaner, safer ingredient labels, we anticipate further global governmental action aimed at reducing or restricting the use of SALP in food and bakery products.

Challenge

Achieving the bright, flaky crumb desired by consumers in American biscuits, along with the distinctive reaction profile brought by SALP in fast-baked, high-temperature goods, presents a formidable challenge. Off-the-shelf acidulants struggle to match SALP’s reaction speed which is crucial for maintaining consistent baking profiles and delivering the desired end product.

Solution

Our OPUS™ SALP Replacer has been scientifically developed to closely replicate the reaction profile of SALP, using a unique blend of acidulants designed to deliver equivalent baking performance. When combined with sodium or potassium bicarbonate, it creates the perfect aluminium-free baking powder for a huge range of bakery applications.

OPUS™ SALP Replacer integrates seamlessly into existing recipes, offering a simple switch from SALP without the need for process adjustments. While SALP’s distinctive 1:1 ratio with sodium bicarbonate is unique, achieving the same high-quality results with OPUS™ SALP Replacer requires only a minor dosage adjustment which our experts can work out for you. This straightforward change ensures consistent volume, crumb structure, and brightness, maintaining product integrity, and removing aluminium from the end-products.

Dough Rate of Reaction (DROR) of

SALP, SAPP and OPUS™ SALP Replacer

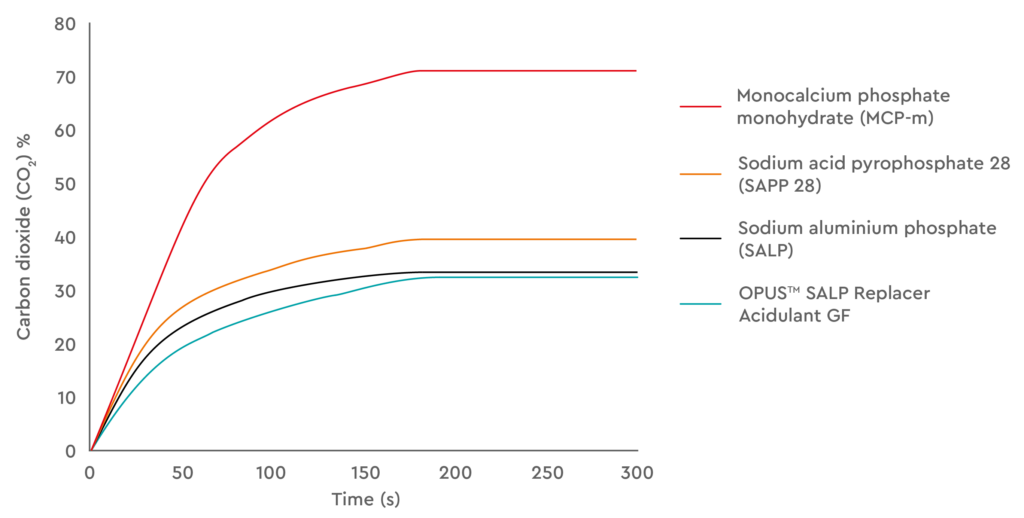

Fig. 1. DROR of SALP, SAPP 28 and MCP-m compared to OPUS SALP Replacer showing the gas release over time in a simulated dough system.

Sodium acid pyrophosphates (SAPP) and monocalcium phosphates (MCP) are other acidulants often used in baking. However, these both have considerably different rates of reactions when combined with sodium bicarbonate than SALP and OPUS™ SALP Replacer.

These differences in rates of reaction translate into the bake, with the product rising and setting at different points, changing the volume, shape and structure of the product. When the gas is released too quickly, you risk the baking powder gassing off too soon in the dough, and the products either won’t get a suitable rise in the oven, due to the reaction occurring too early, or biscuit doughs may end up spreading outwards rather than upwards.

The slower reaction profiles of SALP and OPUS™ SALP Replacer allow for more production of carbon dioxide in the oven, rather than in the dough, just before the starch gelatinisation and the structure sets. This will support optimum end-product volume and shape.

Sodium aluminium phosphate (SALP)

OPUS™ SALP Replacer

The American biscuits were visually similar, with comparable surface and side cracking, as well as consistent heights.

Texture analysis:

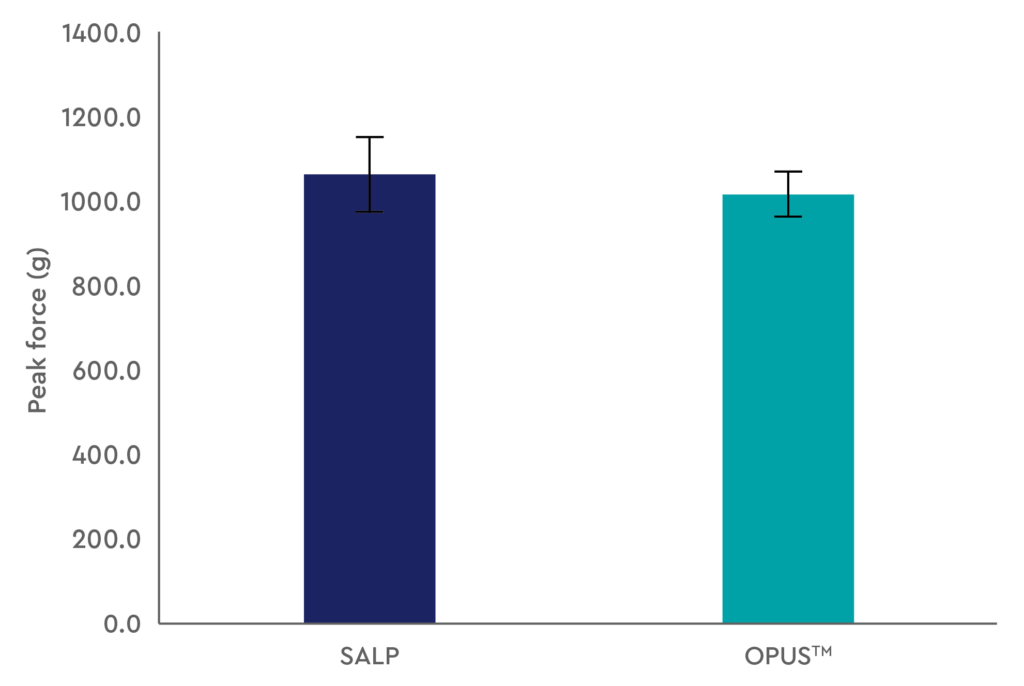

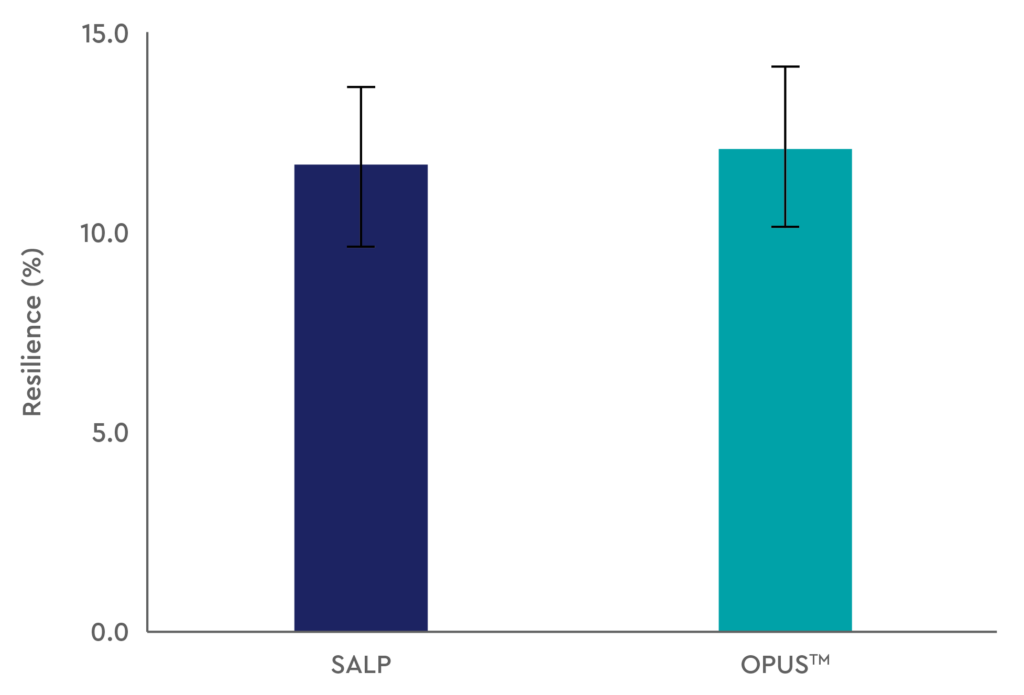

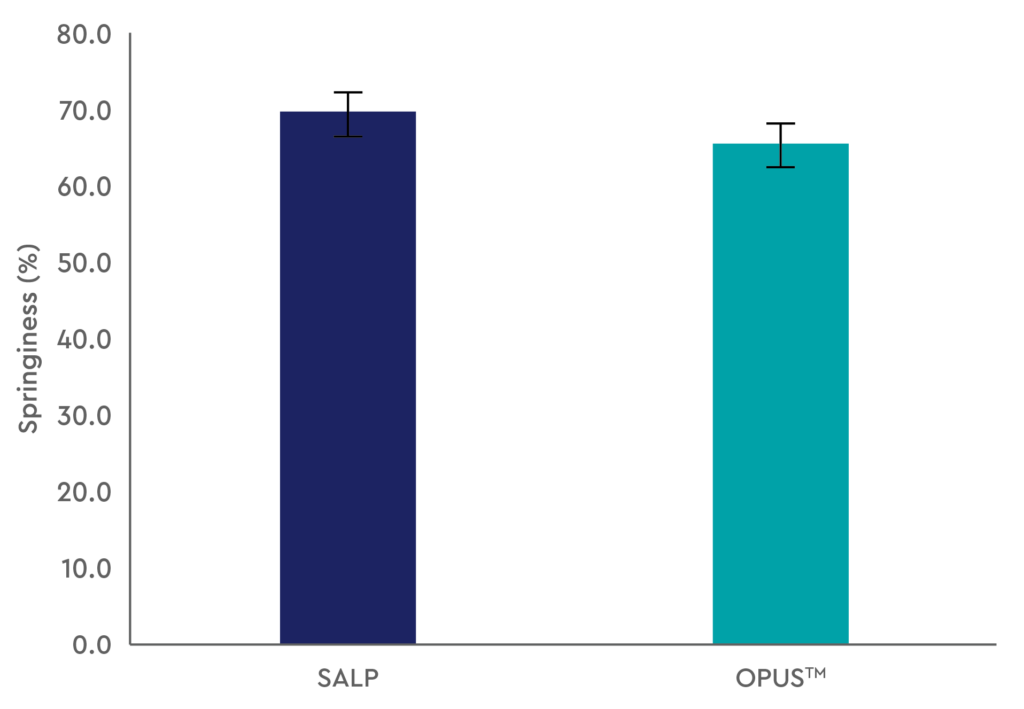

The texture of the American biscuits made with SALP and OPUS™ SALP Replacer was very similar.

Hardness

Resilience

Springiness

OPUS™ SALP replacer isn’t just perfect for American biscuits, but also works wonderfully in cakes, muffins, pancakes, flatbreads and more!

-

Is SALP a baking powder?

No, Sodium Aluminium Pyrophosphate (SALP) is not a baking powder itself, but it is the acid component in many commercial baking powders.

-

Can you get an aluminum free baking powder?

Yes, aluminium-free baking powders are available. Since we are based in the UK, and EU regulations strictly limit the use of SALP in baked goods, all of our baking powders are naturally aluminium-free.

-

Why is SALP so widely used in the bakery industry?

SALP is valued for its controlled release of carbon dioxide during baking and its 1:1 ratio with sodium bicarbonate, making for a simple addition to bakery recipes.