Join us as we delve into the current landscape of bakery colours, exploring the evolution from synthetics to the rise of natural alternatives, and the complex journey towards vibrant, stable, and consumer-friendly creations.

Why Colour Matters in Baking

Colour plays a crucial role in the appeal of baked goods, from the vibrant crumb of a red velvet cake to the layered colours of a rainbow celebration cake. However, behind the visuals lies a rapidly evolving global conversation around what goes into achieving those hues.

As regulatory bodies tighten restrictions on artificial dyes like Red 40, and consumer demand for clean-label and plant-based ingredients increases, bakery manufacturers are under increasing pressure to reformulate recipes.

While natural colourants offer a more consumer-friendly solution, they come with technical limitations, especially in baked applications where pH, temperature, and ingredient interactions can affect colour stability and vibrancy.

This article explores the current state of colour use in the baking industry, highlighting where ingredients are banned, what alternatives are emerging, and the real-world formulation challenges manufacturers must navigate to stay compliant and competitive.

A Short History of Food Colourants

The use of colour in food is centuries old, rooted in the desire to make products look fresher, more appealing, and more indulgent.

Artificial food colours have been widely used since the early 20th century to enhance the visual appeal of processed foods, with Red 40 (Allura Red AC) being one of the most common. Derived from petroleum, Red 40 is prized for its bright, stable colour and affordability, making it a staple in bakery items, beverages, confectionery, and snacks globally.

However, in recent decades, growing health concerns, particularly around potential links to hyperactivity in children and allergic reactions, have put artificial dyes under the spotlight. High-profile studies, such as the 2007 Southampton Study, prompted regulatory changes across Europe, including mandatory warning labels on products containing Red 40.

Today, countries like Austria, Norway, and Finland have banned Red 40 outright in foods, while others, including the United States, India, and the UK, have placed it under active review or regulation. In 2023, California became the first U.S. state to ban Red 3, and more recently, The U.S. Department of Health and Human Services and U.S. Food and Drug Administration (FDA) announced a series of new measures to phase out all petroleum-based artificial dyes, including Red 40, from the nation’s food supply.

This shift reflects a broader movement toward natural and plant-based colourants, as regulators and consumers alike push for cleaner, safer food labels.

While artificial colours like Red 40 remain legal in many countries, their future in food applications is increasingly uncertain.

State of Artificial Colours Globally

Artificial colours face different regulations worldwide, with countries and governing bodies enforcing varying rules for different colours.

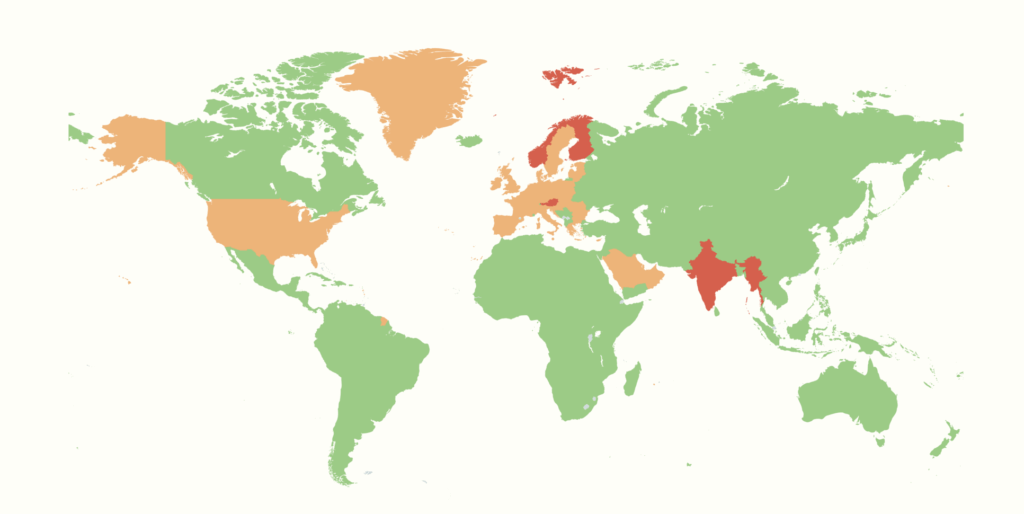

Explore our world map to see where artificial colours are banned, heavily restricted, or face no restrictions at all.

🔴 Red for countries where artificial colours are banned

🟠 Orange where regulations are in progress or restrictions apply

🟢 Green where no restrictions currently exist

Seeing Red – Comparisons

With artificial colours under scrutiny, choosing the right replacement colour for your baked goods is about more than just shade, it is a balance of clean-label appeal, performance, and cost.

This table offers a snapshot of how Red 40, carmine, beetroot, and general natural colours stack up when it comes to what you can say on packaging, why they are used, how they impact budgets, and the real-world challenges bakers face when introducing them into a recipe.

| Red 40 (Allura Red AC) | Carmine (Conchineal) | Beetroot Red | *Natural Colours (General) | |

|---|---|---|---|---|

| Packaging Declarations | E129 | E120 | E162 or Beetroot Red | Varies |

| Origin | Synthetic, petroleum-derived | Natural (insect based) | Natural (plant based) | Natural (Plants, algae, minerals) |

| Use in Bakery | Cakes, cookies, glazes, icing, sprinkles | |||

| Bans and Restrictions | ❌ Banned or labelled in the EU, Austria, Norway, Finland | ❌ Banned in India. Issues with halal/kosher, allergenic | ✅ Permitted globally, but performance and sourcing vary | |

| Key Legislation | EU (Commission Regulation) 1333 and 2008 & EFSA (European Food Safety Authority) 2010: Warning for children’s behaviour | FSSAI (Food Safety and Standards Authority of India) India ban; EU and US allergen labelling FSSAI India ban EU and US allergen labelling required | GRAS (Generally recognised as safe) in the US. Approved under EFSA and FSSAI | GRAS or approved by EFSA. Declaration depends on pigment source |

| Pricing | Low | Medium | Medium-High | Varies |

| Stability | Very stable to heat, light and pH | Fair thermal stability and pH-sensitive | Poor thermal and pH stability | Highly variable. Black carrot (good), spirulina (poor heat), turmeric (light-sensitive) |

| Why is it Used? | Strong colour Cost-effective Easy to use | Natural source Rich red. Strong heritage | Natural Consumer-friendly Vegan | Clean-label appeal Plant-based Wide consumer acceptance |

| Challenges Seen in Baking | Artificial. Linked to behavioural issues in children | Not vegan Allergenic Religious and ethical concerns | Fades or discolours in high-pH and heated applications | Colour shifts, cost, interaction with pH and temperature, variability in supply |

| Consumer Perception | Negative in the clean-label space | Mixed: natural but insect-derived | Positive: plant-based & natural | Strongly positive, though performance must meet visual expectations |

Exploring Alternatives and Why Natural Colours Are Not Always a Natural Fit

In today’s world, consumers are more ingredient-savvy than ever. The push for cleaner labels and transparent sourcing has led to a surge in demand for natural, plant-based food colours. In response to this and regulations, many bakery manufacturers are moving away from artificial additives in favour of naturally derived colours. But while natural colours meet consumer expectations, they bring their own set of functional challenges for formulators.

Natural colourants like beetroot, black carrot, turmeric, and anthocyanin-rich fruit extracts can offer vibrant hues and a more ‘clean-label’ positioning. However, their functionality in baked goods is significantly more complex than their artificial counterparts.

One of the most critical limitations lies in pH sensitivity. Many natural pigments, especially anthocyanins, react strongly to the pH of the finished baked product. While they may appear red or pink in acidic conditions, they can shift to purple, grey, or even green as pH becomes more alkali. This makes colour consistency difficult to control in bakery products, which typically have a neutral to slightly alkaline pH.

This photo showcases just how natural colours can behave differently across various applications. While the liquid form maintains a stable, vibrant red hue, baking the same colour in a cupcake alters its appearance. Factors like heat, pH levels, and interactions with other ingredients can cause the colour to degrade or completely change during baking.

Right: Beetroot based red powder baked into a cupcake using a standard baking powder.

Unfortunately, changing the pH to help stabilise natural colours in a baked product is not as simple as it sounds; the smallest changes can impact how much or little the product rises and how it tastes. To protect colour integrity, manufacturers often resort to adding acidic compounds (like citric acid) to a recipe to lower pH and stabilise colour. While this can help preserve the intended hue, it introduces new formulation problems, especially when paired with baking powder.

Additions of acid can prematurely activate the leavening reaction, causing gas release too early in the process. This results in:

- Lower volume

- Dense or gummy crumb structures

- Underbaked visual appearance, even when the product is fully cooked

These side effects increase waste, create quality control challenges, and can negatively affect a brand’s reputation for consistency, all while driving up costs.

A Delicate Balancing Act

At Kudos Blends, we understand that meeting market demands for natural, recognisable ingredients must not come at the expense of product quality or production performance.

That’s why we offer comprehensive support to progress customers’ natural colour projects from concept to completion. With the right baking powder, natural colour, and recipe formulation, it is possible to maintain both colour impact and finished product quality, ensuring consumers get the cleaner-label products they want without visual or textural disappointment.

The Bottom Line

Natural colours offer a compelling way to meet growing demands for ingredient transparency and clean labels, but they come with technical trade-offs. Success in this area hinges on smart ingredient pairing, careful pH management, and leavening systems that support colour retention without sacrificing structure or performance.

If you are navigating the switch to natural colours and need a baking powder that works with your formulation, get in touch with our experts.